Condition Based Monitoring & Inspection Services

Infrared Thermography

Infrared thermography is a science of using infrared technology to detect radiation emitted from an object and convert the radiation energy into temperature reading, then reproduces the image into temperature distribution diagram, which called thermagrams.

It is one of the non-destructive thermal methods which is becoming ever more popular in nondestructive testing of materials and structures.

In the field of engineering, the application of infrared thermography is not limited to passive investigations of the quality of thermal insulation of building envelopes.

Defects like voids in concrete or masonry, delaminations at interfaces of composites which have different density, heat capacity and heat conductivity in comparison to the bulk material can be localised and characterised.

Baytech Resources provides infrared thermography analysis for detecting defects in equipments and machineries. The advantages of using the technology:

Ultrasound Inspection

Ultrasound inspection provides early warning of partial discharge activities, bearing failure, detects lack of lubrication, prevents over lubrication and can be used on all bearing speeds (high, medium and low).

It is a very useful and versatile NDT method. Some of the advantages of ultrasound inspection are:

Due to its versatility and cross-integrated with other condition base monitoring such as thermography and vibration technology, ultrasound inspection is a compulsory method that would be used to inspect your asset.

Baytech Resources’ certified ultrasound inspectors utilise advanced instrumentation and data reporting capabilities to quickly and accurately detect flaws and measure material depth for a variety of applications and industries.

Contact our experts at Baytech Resources to find out more about our ultrasound inspection now.

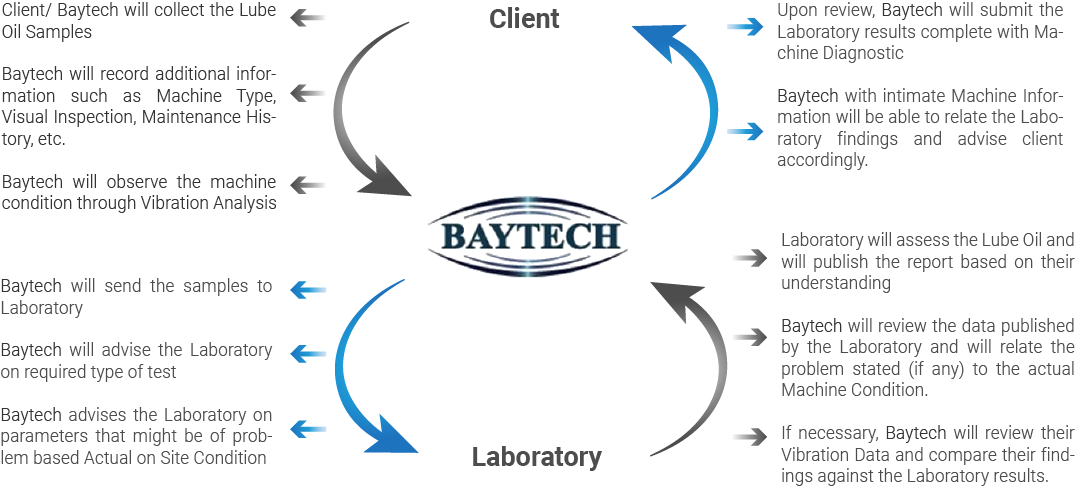

Tribology & Lubrication Oil Analysis

Vibration Analysis

Online, Offline and Wireless, Reciprocating Compressor & Engine, ODS, Experimental Modal Analysis, Motion Camera Analysis etc.

Advanced Engineering

Structural Design

- Structural dynamics - pipes & structures

- Fatigue life & crack propagation prediction - boiler tubes, rotors

- Structural dynamics assessment

- Finite Element Analysis (FEA) - structures, pipes & complex weld geometries

Piping Design

- Small Bore Fittings – (SBF) fatigue assessment

- Fatigue & crack propagation prediction

- Computational Fluid Dynamics (CFD) - 2 phase flow, condensate

- Acoustic Induced Vibration (AIV) - high pressure lines

- Flow Induced Vibration (FIV) - pipe supports & hangers

Equipment Package

- Compressor pulsation studies

- Blast & over pressure - modelling & analysis

- Stress, strain & torsional - modelling & analysis

- Fitness for Service (FFS) for aging GT, GTG etc.

Advanced Engineering Analysis

Piping and structure vibration testing according to AVIFF, Flow Assurance, CFD, FEA etc.

Why Baytech Resources?

Baytech Resources will further enhance your asset integrity and maintenance management system by focusing and prioritizing of potential fault due to the inefficiency of equipment operation or maintenance.

This will also serve as fitness assurance for equipment reliability and operators safety during day to day routine operations. Baytech Resources provides pinpoint accuracy and specific solution which guarantees the system uptime improvement and availability.